Indicators on Dust Extractors For Small Workshops You Need To Know

Wiki Article

The 25-Second Trick For Dust Extractors For Small Workshops

Table of ContentsThe Greatest Guide To Dust Extractors For Small WorkshopsDust Extractors For Small Workshops for DummiesHow Dust Extractors For Small Workshops can Save You Time, Stress, and Money.The Best Strategy To Use For Dust Extractors For Small WorkshopsThe 10-Second Trick For Dust Extractors For Small Workshops

Some industries that use baghouse systems are powder finishing business, cement plants, paper producers, as well as rubber recycling. Dust cakes on the outside of the bags as well as is gotten rid of down right into collection receptacles by a blast of pressed air or activity.

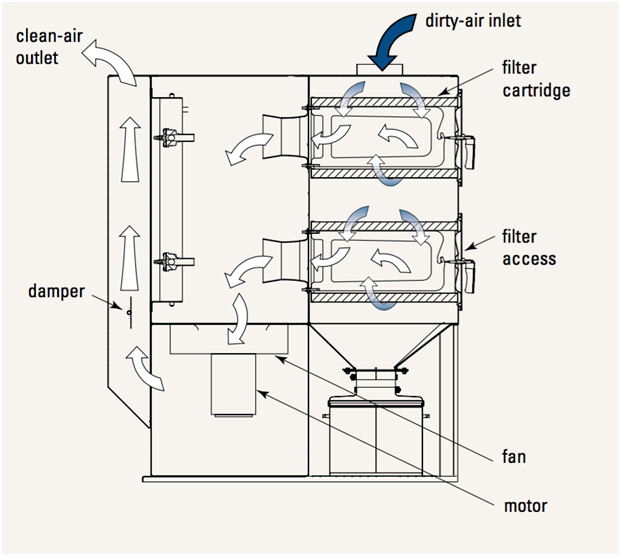

The straight system enables for permanent as well as perfect cartridge placement without yokes, sagging, or fracturing. Gaskets produce a limited and safe and secure seal along the housing and also filters. Vertical cartridge dust accumulating system replaces bags with round or oval-shaped cartridges that are open on both ends and are lined with pleated filtering system media.

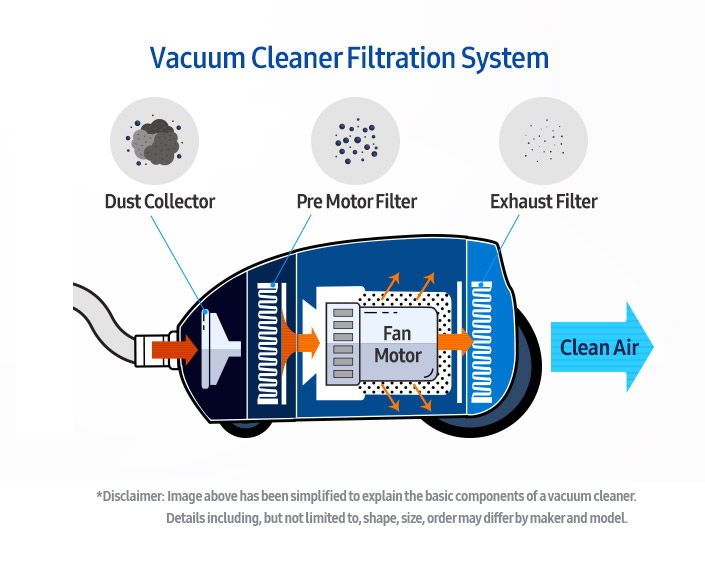

The air stream is required via the outside of the cartridge to the inside. The cartridges are maintained tidy by compressed air blown into them, which gets rid of built-up dust that falls under the receptacle below. A wet scrubber dirt collection system uses droplets of water to record the dust bits.

What Does Dust Extractors For Small Workshops Do?

As the rotation increases, a mist remover forces the saturated dust bits into the disposal device. When the dust bits are saturated with water, they increase in size, which makes them easier to get rid of.

They are mobile dust collection systems that function as an office and also are made use of for small jobs. To enable for air movement, the top of a downdraft table is perforated.

A viable service for dust collection for procedures that develop dirt as component of production and also processing is a self-contained, inner return dirt collection system that uses a set of followers, filters, and also collection bags to remove dust from workstations as well as manufacturing. They are a favorable stress bag collection agency made use of in centers where bits do not get to the submicron degree.

This kind of system is the least pricey and very efficient. It is developed to gather timber chips, plastic fragments, and also products that collect on strong surfaces. In addition, the system is totally self-contained, indicating that it does not discharge air into the environment as well as is available in sizes to fit any type of operation.

Dust Extractors For Small Workshops Things To Know Before You Get This

The effectiveness of an ambient dirt collection system can alter the air in a structure. dust extractors for small workshops. A capture system that makes use of hoods, arms, and capture factors becomes part of an ambient dirt collection system. As the cleaned air go back to a building, it requires filthy air into the ambient dirt collection system.

The major function of a push-pull ambient system is cleansing the air as well as returning it. This differs from a system that cleans the air as well as releases the clean air outside the structure, which can be inefficient. The push-pull approach is very effective as well as energy-saving and also benefits from home heating and cooling systems that do not exist with air being vented outside.

The setup of NPBI technology enhances indoor air top quality for healthier working conditions. Filters give filtering for the air while the ionizers take the exhaust and also provide it easy air purification to enhance the air being gone back to the structure. The ions from the system relocate the airstream as well as tidy the air all over, also in hidden locations.

Some Ideas on Dust Extractors For Small Workshops You Need To Know

As they go into the airstream, they attach to fragments, virus, gasses, as well as smells, including submicron fragments. The particles come to be attracted best site per other and also are large enough to be conveniently filtered. The ions eliminate the particles by eliminating their hydrogen, which is necessary for their existence. Filtering systems are a preferred form of dust collection, there are systems that do not utilize filters.As bits pass with the system, they are ionized and also billed, which creates them to be accumulated on a collecting plate. Electrostatic precipitator dust collection agencies (ESPS) are efficient with big air flow.

An issue with ESPS systems is exactly how gradually bits handle an electrical fee. For the system to be reliable, the fragments in the air should be capable of taking on a charge rapidly for fast elimination. The major feature of dirt collection agencies is to gather dust as well as clean the air.

These risks require special explosion-proof dirt enthusiasts that have systems to stop and also regulate explosive materials. The very first step in picking an explosion-proof dirt collection system is recognizing the kinds of dust page a process creates. Different kinds of dirt need to be regulated and also checked differently in order to be regulated.

The Only Guide for Dust Extractors For Small Workshops

It is very important to understand that all organic dirt is eruptive as well as calls for an explosion-proof dust enthusiast. In cases with possible explosive or flammable fragments, the process begins with "go or no go" screening, where dust is sent to be reviewed. The process assists in picking Resources the correct dust accumulating system.Report this wiki page